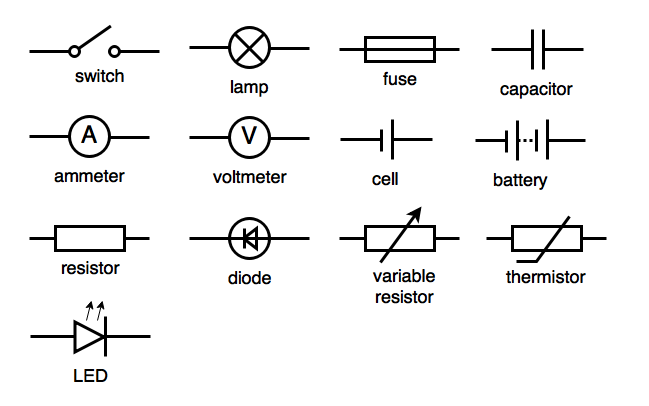

Overcurrent Protection (Over Current)

Automatically disconnects the power when the current exceeds a safe level, preventing damage to circuit components due to excessive current.

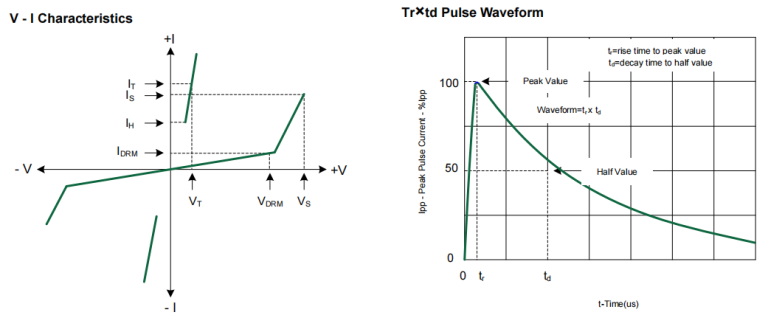

Overvoltage Protection (Over-Voltage Protection)

Primarily prevents damage to electronic components from overvoltage or electrostatic discharge (Discharge Suppression). It is widely used in various electronic systems such as telephones, fax machines, and high-speed transmission interfaces (USB, IEEE1394, HDMI, SATA), especially in electronic communication equipment. Avoiding damage from abnormal voltage (Over-Voltage or EOS (Electrical Over-Stress)) or electrostatic discharge (ESD) is particularly important.

Overtemperature Protection (OT)

Temperature protection components have been commercialized for more than 60 years. Currently, they are widely used in applications with specific temperature requirements. These protection components can be classified into chemically actuated types and low-temperature alloy actuated types based on their operating principles. The main characteristic of chemically actuated products is that they can be designed for low-temperature operation (currently down to 48°C), but they have a more complex structure and higher cost. Low-temperature alloy actuated types mainly use a larger diameter low-temperature fuse for conduction. It must be ensured that the heat generated by the rated current does not melt the fuse. The melting point of this low-temperature fuse is typically adjusted by varying the proportions of tin (Sn), copper (Cu), silver (Ag), bismuth (Bi), and indium (In).

Thermal Fuse with Reset (TFR)

In recent years, with the advancement of applications, simple temperature protection functions can no longer meet the safety protection needs of rapidly evolving electrical appliances, motors, and 3C products. Therefore, components that can simultaneously monitor and provide timely protection against abnormal temperature, current, and voltage conditions have been developed. The rise of these components is primarily driven by their extensive use in lithium-ion and lithium-polymer batteries.

Overcurrent and Overvoltage (OCOV)

With the increasing complexity of modern electronic products, the requirements for protection components have also become more stringent, such as comprehensive protection and limited space. As these requirements have emerged, there has been a surge in the trend of combining multiple protection functions into a single package. For example, the combination of overcurrent and overtemperature protection is one form of combined packaging. However, the combined packaging of overcurrent and overvoltage protection is still largely in the development stage, and there are currently no mature commercial products available.